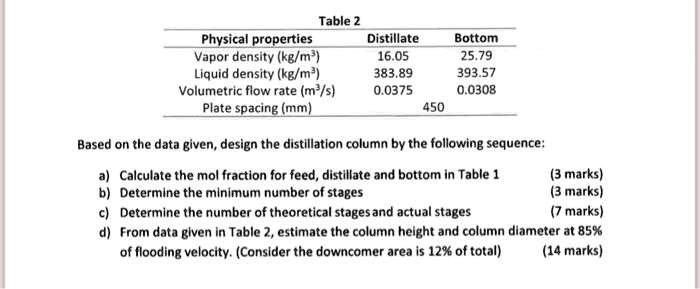

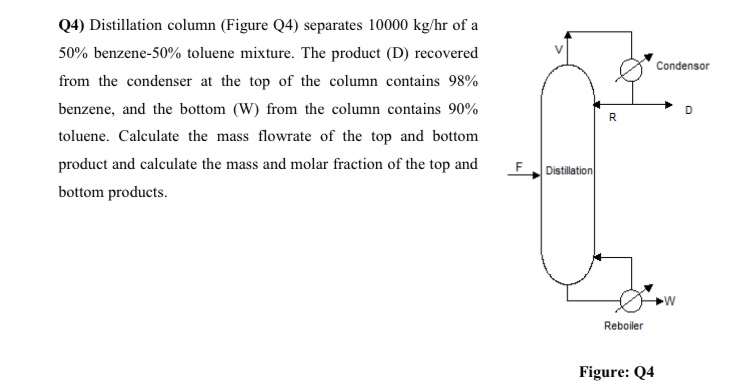

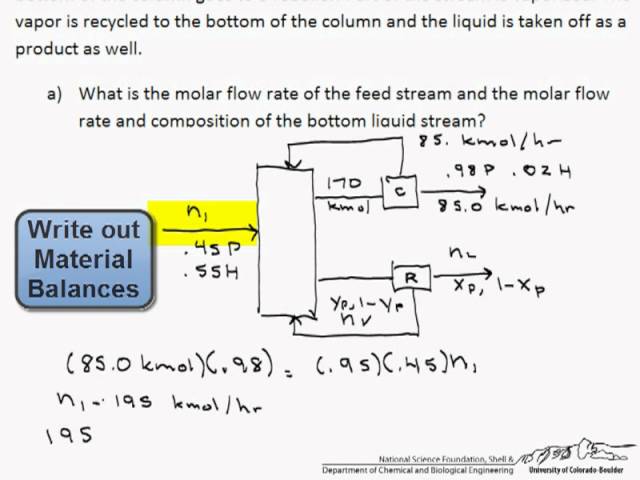

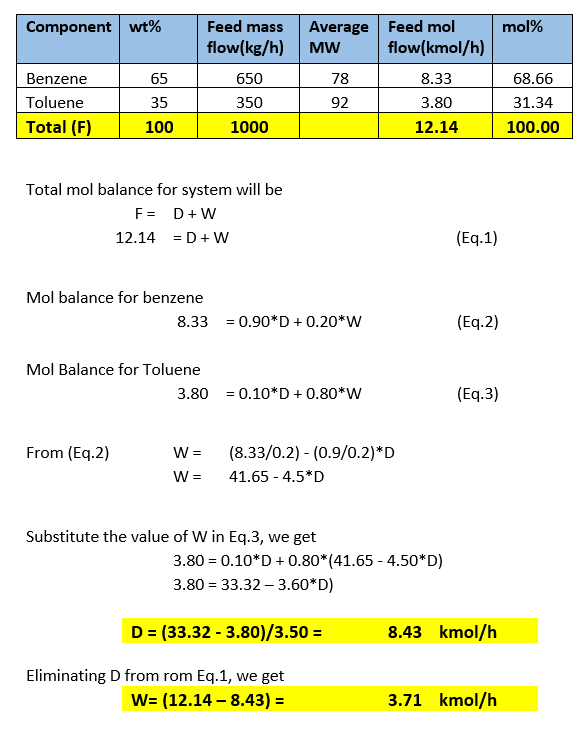

One thousand kilograms per hour of a mixture containing equal parts by mass of methanol and water is distilled. Product streams leave the top and the bottom of the distillation column.

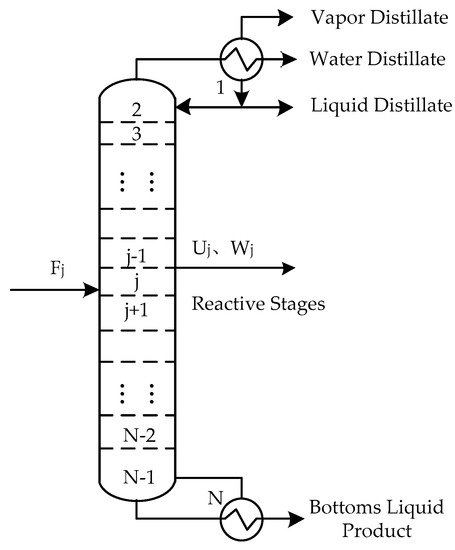

Optimization-Based Design of a Reactive Distillation Column for the Purification Process of Cyclohexanone Using Rigorous Simulation Model and Validated Using an Experimental Packed Column | Industrial & Engineering Chemistry Research

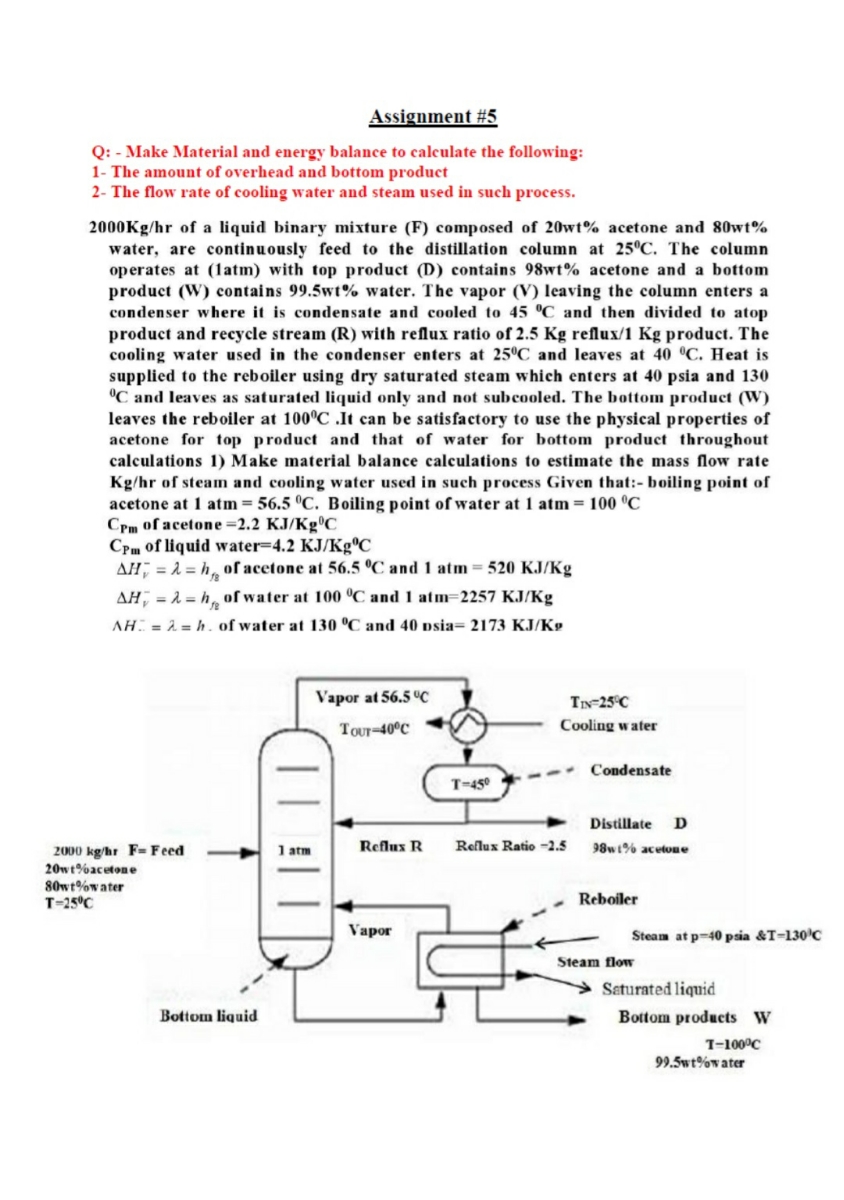

PDF) Determination of the Flowrates of Vapour and Liquid in a Binary Distillation Column using MS Excel

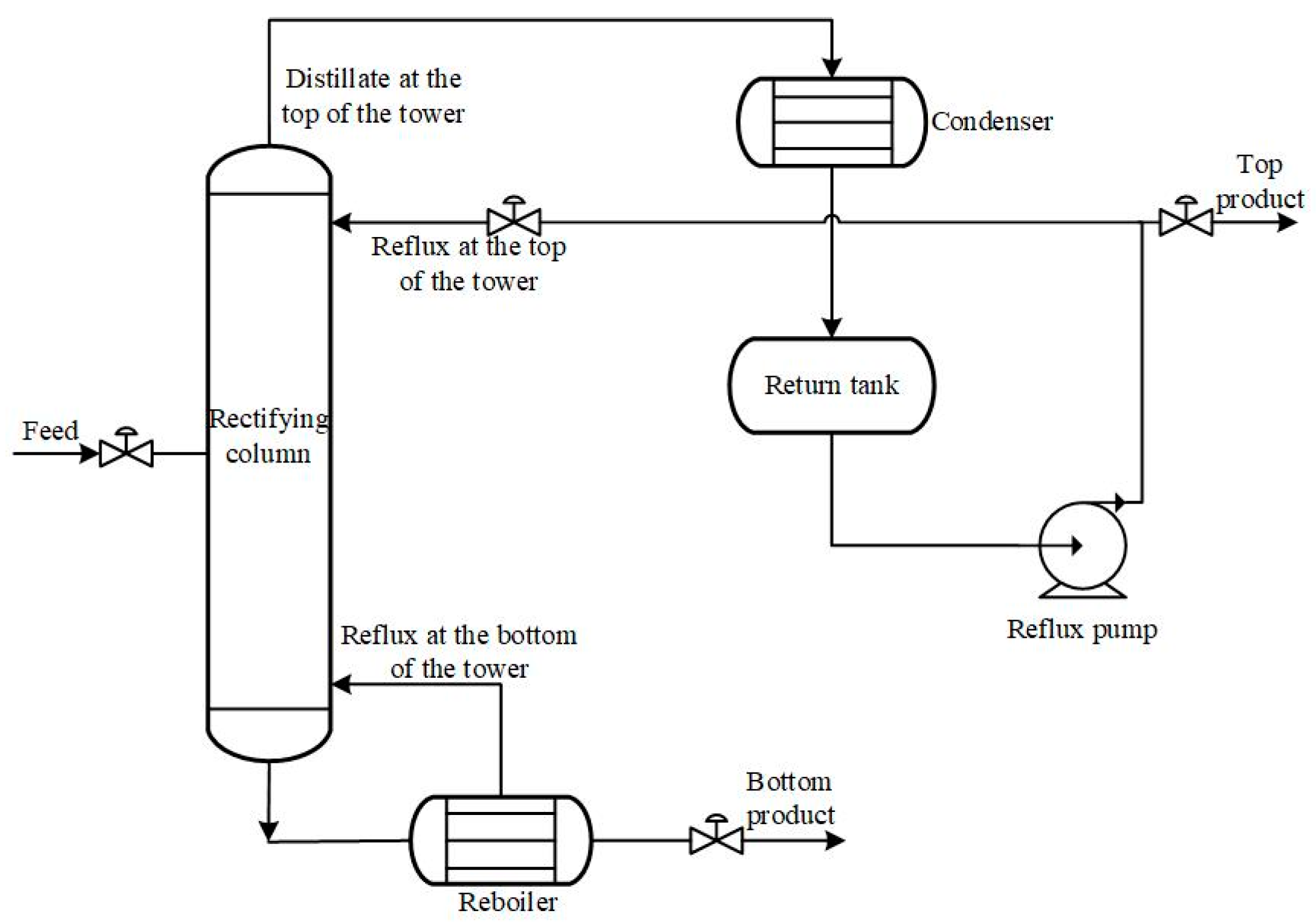

Flowsheet of the program to calculate a rectification column optimising... | Download Scientific Diagram

Processes | Free Full-Text | Modeling and Control Design for Distillation Columns Based on the Equilibrium Theory

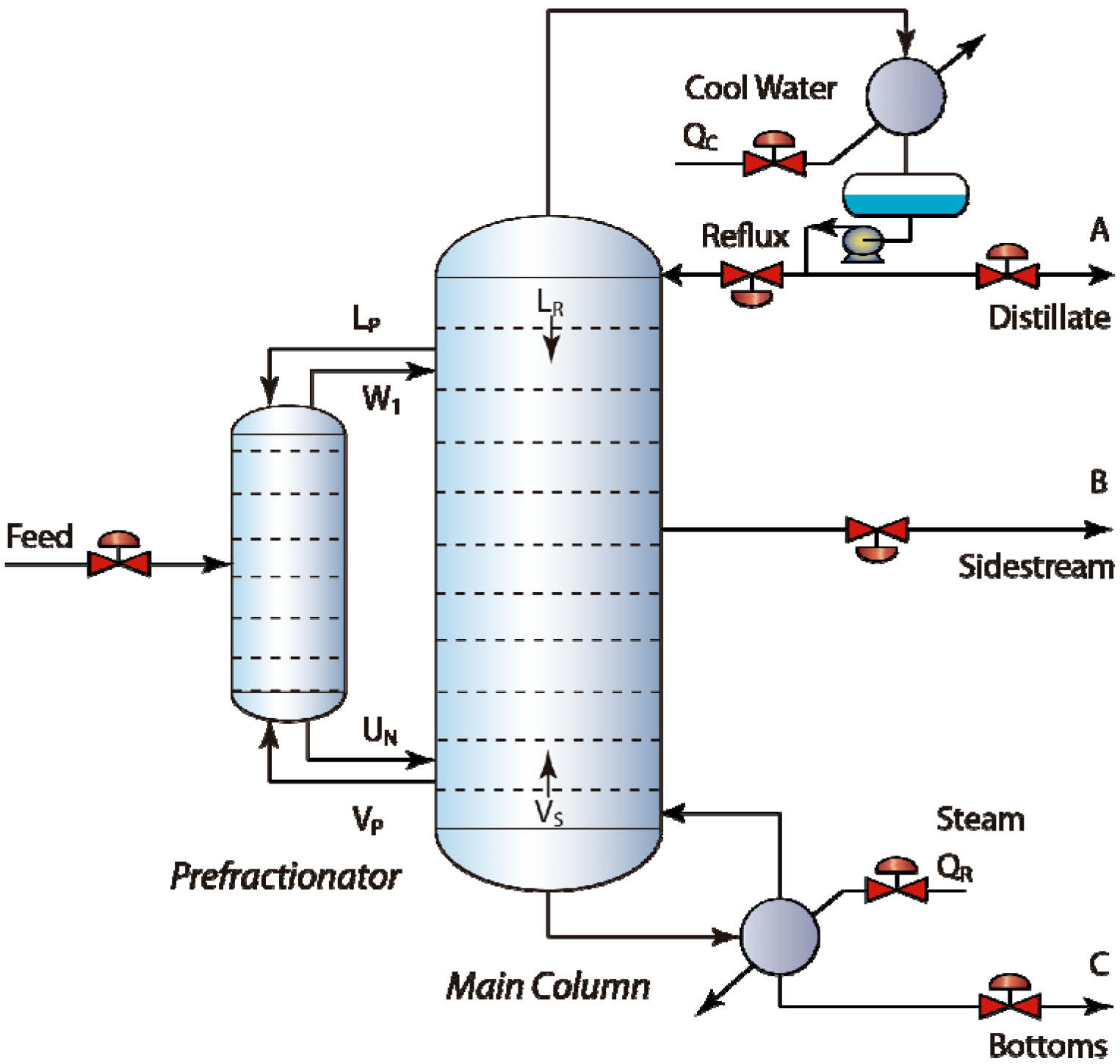

Processes | Free Full-Text | Analysis of Multi-Loop Control Structures of Dividing-Wall Distillation Columns Using a Fundamental Model